The traditional model of manual judgment based on experience

Lead to long cycle, low operation, poor profitability

Establish a harmonious and unified energy wisdom cube to pull the project service link

Deep service,

reduce project cost, increase project income

The traditional model of manual judgment based on experience

Lead to long cycle, low operation, poor profitability

Energy services six links

Lack of uniformity in project execution

Separation of construction, management and operation

Data quality cannot be guaranteed

Multifaceted solutions are required

Meet policy requirements

The effect can be fairly certified

Heterogeneous data from multiple sources

System coupling characteristic

Multiple variable parameters

Operations staff aging age structure and knowledge structure

Need to reduce dependence on people

The safety, reliability and stability of energy use are very high.

Equipment operation safety in passive management, lack of active preventive measures;

Alarm and operating conditions exist in different systems, which is easy to form island effect.

It is difficult to trace the result of alarm processing effectively.

The lack of unified supervision service in logistics operation and maintenance leads to low work efficiency;

Where is the real effective incentive of the logistics team and how to evaluate the performance;

Talent flow, experience is difficult to integrate, personnel age is too old;

Logistics outsourcing, responsibility can not be outsourced, how to assess the work of logistics outsourcing companies;

Lack of comprehensive analysis of system energy efficiency and equipment working conditions, and opaque energy consumption;

Unreasonable design in the early stage, passive transformation in the late stage, waste of resources;

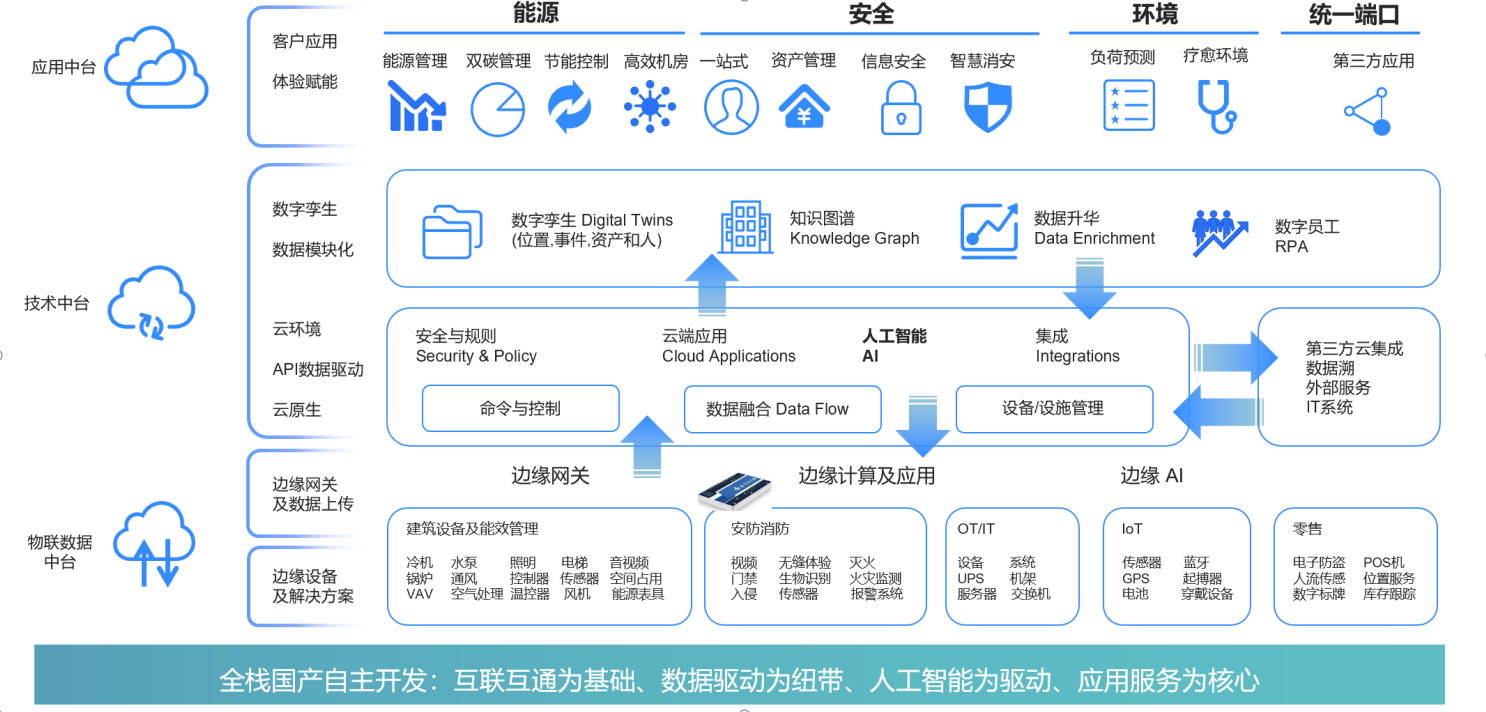

In the face of the digital platform for the scenario, built a set of intelligent hospital operational management process based data standards.

Self-developed equipment and facilities system configuration editor, page editor, report editor and so on. The system can be configured by means of pulling and connecting.

Through the completely self-developed data acquisition gateway E-AIOT-Sentry, converted into MQTT protocol access digital platform.

The platform has built-in alarm processing engine, equipment operation diagnosis engine, equipment health engine and other engine drivers to quickly complete data rules and data applications.